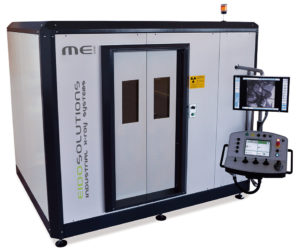

The X-ray equipments produced by Eidosolutions are suitable for X-ray inspection of a wide range of components as aluminum, steel, plastic and composits. They are high quality systems, fast and versatile, that can be used both in production and in laboratory, they uses the latest technology available and are equipped with our image processing software Delfis.