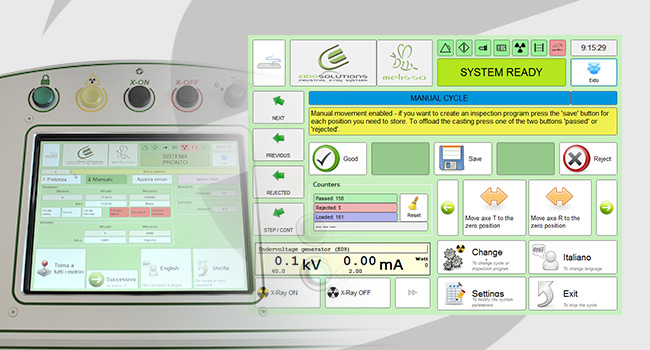

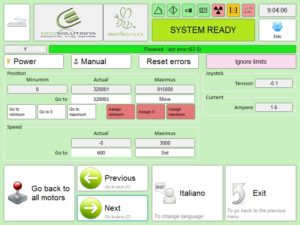

All Eidosolutions equipment implement a large number of subsystems such as motors, IO modules, X-ray devices, security modules, and more. Melissa aims to interface with these systems and allow the user to use the unit in the simplest and most effective possible way by providing the necessary functions.

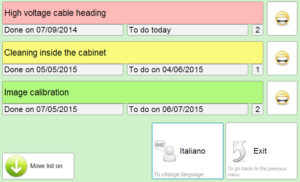

Melissa is entirely developed within Eidosolutions with constant enhancements, upgrades and new features (even customized).

The underlying philosophy of this software is to provide a very simple and intuitive interface that can be easily used with touch monitor; The learning curve is very fast and after an 8 hour course and a few days of practice the operator is able to use most of the features with good mastery.